Manufacturing Process of A Set of Classic Leather Sofas

- By:ARTSOME

- 2022-07-09

- 522

1.History

Sometimes called a couch or a davenport, a sofa is a long upholstered seat with both arms and a back. Today, it is a common luxury indicating that humans are moving away from the nomadic “pack and evacuate” lifestyle of our recent past.

The origin of the sofa can be traced back to ancient Egypt around 2000 BC, but the true meaning of the upholstered sofa appeared in the late 16th century to the early 17th century. Ancient Egyptians and their Roman contemporaries reserved the items for royalty and other social elites. In the West, interior decoration as we know it today developed slowly as building architecture improved. Fabric was first used to protect against the cold, and then gradually used for decoration and on individual pieces of furniture. Contributions to interior design were made from all major European centers. Germans introduced the use of horsehair padding, which was still a central feature of properly upholstered furniture. The English preferred dried sea moss. Italians introduced backrests and arms during the Renaissance. Upholstered chairs had been invented already, but were not popularized until this time. The sofa with a down cushion was an extension of the upholstered chair.

The eighteenth century “upholder” was a combination of designer and decorator who completed an architect’s vision of a room. During the nineteenth century, the advent of industrial technology had a major impact on modern methods of upholstery. In 1850, coil springs were invented. A modern sofa typically, though not always, contains springs to even out weight distribution. The sewing machine was also developed during this period, speeding up the upholstery process. New improvements such as modern welting would not be possible without the sewing machine.

2.The Basic Structure of a Classic Leather Sofa

The nice leather and stylish frame may be the reason you fall in love with a classic sofa or chair, but if you neglect what’s inside, your feelings may fizzle over time. A classic leather sofa is mainly composed of three parts, framework, filling material and finish. Framework is mainly to meet the requirements of shape and strength. The filling material plays a decisive role on sofa comfort . The traditional filling material is palm, spring, and now commonly used is all sorts of function of foamed plastics, sponge, synthetic materials and so on. Filling material should have good elasticity and fatigue resistance with a long service life. The grade of sofa depends on the texture, color and luster of the fabric. With the progress of science and technology, the variety of fabrics will be more and more abundant.

3.General Manufacturing Process

Sofa production features a variety of materials used, large difference of material, making framework with lumber, steel products, man-made board, paint, decoration, filled with sponge, foam plastic, elastic, non-woven fabrics, springs, mat, and making finishes with cloth, leather, composite material. Another features is a large processing span, from the carpentry, painting, sewing to assembling. Based on the principle of professional division of labor, and of improving work efficiency, sofa processing can be divided into four stages: frame section, cushioning section, upholstery section and assembling section. In different sofa factories, the technological process is also different. Specialized division of labor is beneficial to improve work efficiency and ensure the stability of product quality.

Sofa production need to go through a lot of complex operation steps, and the first step is the design. Designers should be based on their own design experience, combining with the classic elements for product creativity. Then after a precise calculation, they will draw a full set of sofa drawings, including the size of each component, material and so on. The craftsmen will produce the classic cow leather sofa according to the design drawings.

1.Frame Section

The frame is constructed from solid wood that has been found clear of any defects. The thickness of the wood should allow for the heavy tension webbing to follow. If the frame is not sufficiently strong, it will not bear the weight redistributed into it by the webbing whenever someone sits down. Frame materials are mainly solid wood, steel, plywood, medium density fiberboard (MDF), which joined via various joinery techniques plus staples and/or screws and other hardware.

First, the wood cutting workshop will complete the corresponding dosage according to the design drawings and the order quantity. Then the wood materials should be polished and trimmed or painted. Frames are made by joining pieces of wood together. The joints are typically the weakest part of the frame. Different types of joining methods include:

- Mortise & Tenon: The strongest method, this is used when two pieces of wood meet at a 90 degree angle. One piece of wood has a hole and the other is cut to fit precisely into that hole.

- Double Dowel: A dowel is a small, wooden cylinder. It gets inserted into a small round hole drilled into two pieces of wood to hold them together. A double dowel is just what it sounds like, two wood dowels at each joint. While not as sturdy as a mortise and tendon, and more likely to loosen over time, this is still a perfectly acceptable method that is found on many upholstery frames.

- Corner Block Reinforced: Corners are weak points on wood furniture and need to be reinforced. An extra piece of wood (usually triangular) is placed at an angle, glued and stapled or screwed into place.

- Reinforced Joinery: This describes adding an extra layer of support to keep things in place. The joint could be reinforced with glue, screws, or staples.

A flexible support surface is needed for the sitting area and the back area. The most used materials are special composite elastic rubber bands, which are stapled evenly to the frame via a nail gun. An alternative would be bow springs, which can increase the bearing capacity of the sofa. Then fixed them by using a special spring clamp to reduce noise. This basic structure could be covered also with a layer of non-woven sheet of protective fabric, which can be effectively moisture-proof breathable.

2.Cushioning Section

Cushion construction is the single most important factor in determining the lifespan and comfort of your classic cow leather sofa. Most upholstery cushions are made from some type of polyurethane foam. However, depending on the product’s design, the back and seat cushions may include a combination of springs, cotton or polyester fiber, foam or down.

First of all, cut out different shapes of sponges or foams and pad the down feather bags according to the shape of the sofa. Next, paste the sponge or foam of different density according to the design requirement. Finally, cover the outermost fabric, a piece of vintage cow leather.

Padding is the material that goes over the frame and directly under the upholstery fabric. Its function is to fill out and firm up the contours of the sofa so that the fabric sits smoothly and fits perfectly all around, without wrinkles or puckers. Insufficient padding can result in feeling the uncomfortable hardness of the frame. Padding also acts as a buffer along the arms and back of a piece where friction and wear show up first, as on corners and edges. Foam or cotton padding are often used, sometimes mixed with other insulating materials.

3.Upholstery Section

The choice of finish colors, patterns, and textures is almost unlimited, but there are only two basic categories of covering components, natural and synthetic. Natural components include cotton, linen, silk, wool and, of course, leather. Synthetic materials include acetate, acrylic, nylon, rayon and polypropylene. Many fabrics are made from a mixture of natural and synthetic fibers. Fabrics that combine a tight weave with a durable fiber, such as nylon or polypropylene, are a good choice for active use. Leather is also a popular choice for durability. All the leather used on Artsome furniture are Italian top grain cow hide leather, which is the high quality and luxurious in the furniture world.

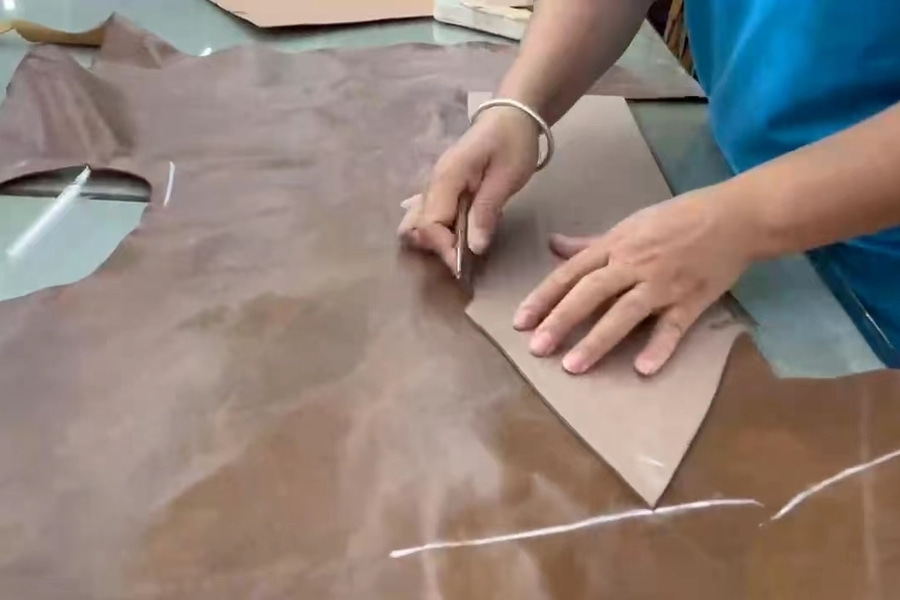

The first step is to select the appropriate cowhide for tanning according to the production order. After tanning, according to the ingredients list, cut each piece of the vintage cow leather with template. It can also be scratched with a blade. Examine the cow leather sheet by sheet to avoid scars and defects. After cutting, each piece of cow leather of sofa cushion, armrest, back should be sorted and packed, so that the next procedure, sewing, can work smoothly and efficiently.

Sewing is a very important process in the sofa making, related to the appearance and technological level of a set of sofa. In most sewing, machine sewing is the first choice for the craftsmen, but there are some positions that need to be stitched by hand, as the machine stitching does not meet that requirement.

1) Trial Sewing

Trial seam is to temporarily sew two pieces of leather together, and use trial seam to stitch together. Trial seam is mainly used to position the leather, which is convenient for inspection and adjustment. Trial stitches can be made with pins or wide stitches. The pins or sutures used for trial sewing should be removed after the formal sewing.

2) Sew with the Fiber Cotton

Line up the leather material with the fiber cotton, with the leather on top and the fiber cotton on bottom, and press evenly to the sewing machine. The soft fiber cotton is sewn close to the inside of the leather and outside the sponge, which can ensure that the sofa is soft enough when used. After sewing, use scissors to trim the excess fiber cotton.

3) Plain Seam

Put two pieces of leather together with both hands and press them to the sewing machine, ensuring that the top and bottom of the leather are at the same speed during sewing. The edges between the two leathers should be overlapped when sewing. Generally, there is a sewing width of about 12mm on the outside of the leather, and the sewing width of thick leather should be increased to about 20mm.

4) Double Stitched Seam

A double stitched seam is the same as a plain seam but with two rows of parallel stitching on the leather’s right side, either side of the original seam. This results in a more robust seam. The double-stitched seam is often used for decoration, especially with leather upholstery.

The last but not least step is checking. Check whether the folds are uniform and symmetrical. Check whether the surface of the leather is neat, and whether the sewing line is straight, smooth, without a knot. Pay attention to the leather color whether it is consistent, and to the pattern whether it is symmetrical.

4.Assembling Section

At this stage, craftsmen will assemble the semi-finished products from various workshops, such as the seat cushions, finishes and sofa feet.

Cover the classic sofa frame with sewn vintage cow leather. According to the appearance of the sofa, fix the sewn vintage cow leather with gun nails in the appropriate position. In addition, add a few metal ornaments, such as copper nails that are treated with special antique method, showing vintage style of the sofa. A piece of cambric will be covered at the base as a dust cover supplied with a zipper, so that some installation parts of the detachable feet can be stored during packing.

After the assembly of the sofa, it need to do multiple quality testing. If there is no problem about the testing, it will be packed and put into storage, waiting to be shipped around the world.

-

The Exhibition – The 55th CIFF Guangzhou

2025-03-04 -

New High Back Elephant’s Ear Sofa

2025-02-12 -

Sophisticated Dining Set with Ash Wood Frame and Green Leather Chairs

2025-01-16 -

Merry Christmas & Happy New Year

2024-12-25 -

Luxury King Size Bed

2024-12-23 -

White Linen Cloud Sectional Sofa: A Symphony of Comfort and Style

2024-11-28 -

Stainless Steel Furniture — Kalas Desk And Saddle Leather Chair

2024-11-04 -

Versatile and Stylish Storage Solutions: The Elegance of Wooden Trunk Designs

2024-10-16 -

The Exhibition: Canton Fair 2024 (Autumn)

2024-09-28 -

Good Show at Funiture China 2024 Shanghai

2024-09-21

-

Egg Chair & Swan Chair, the Iconic Symbol of Scandinavian Design

2023-11-13 -

Vanity Fair Sofa, the Luxurious and Stylish Furniture

2023-10-04 -

A Guide for Modern Metal Furniture

2023-08-15 -

Introduction of Modern Furniture Material — Acrylic and Glass

2023-07-15 -

The Structure & Materials of Artsome Leather Sofa

2022-12-16 -

Modern Furniture Finishes & Furniture Care Tips

2022-11-14 -

How to Design the Modern Furniture Sofa

2022-10-02 -

Tips for Looking for a Quality New Bed

2022-09-13 -

Tips for Mid-Century Modern Furniture Placement

2022-08-19 -

Types & Identifying Tips of Cowhide Leather

2022-08-06